Anaerobic and Honey Processed

Anaerobic and honey processes bring new, and different qualities to the coffee beans. There are many variables, and many different characteristics can be achieved with different timings, and conditions.

Anaerobic and Honey Processed

Anaerobic and honey processes bring new, and different qualities to the coffee beans. There are many variables, and many different characteristics can be achieved with different timings, and conditions.

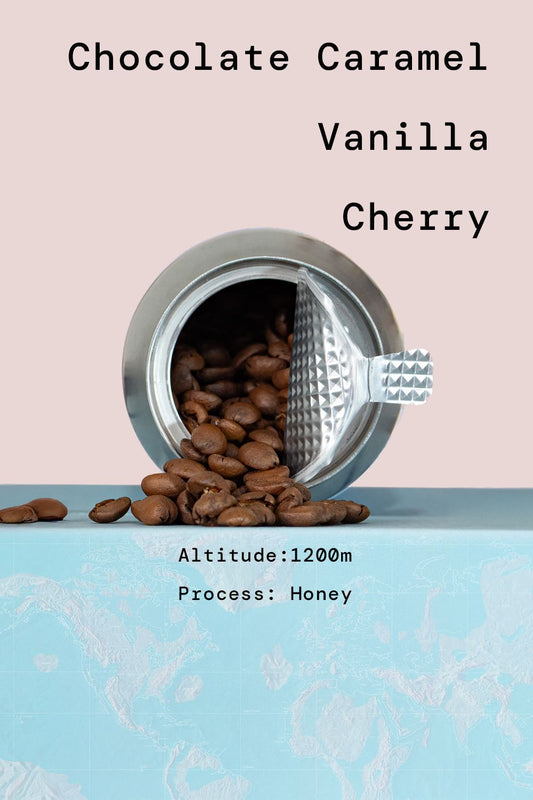

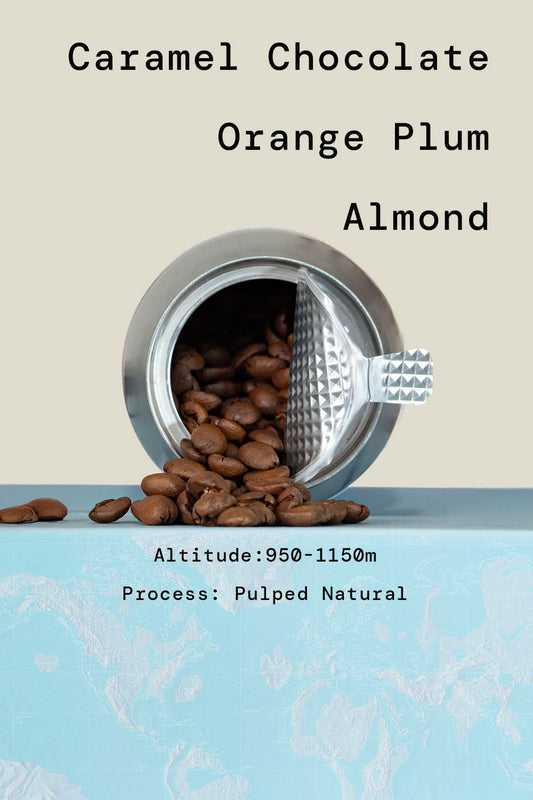

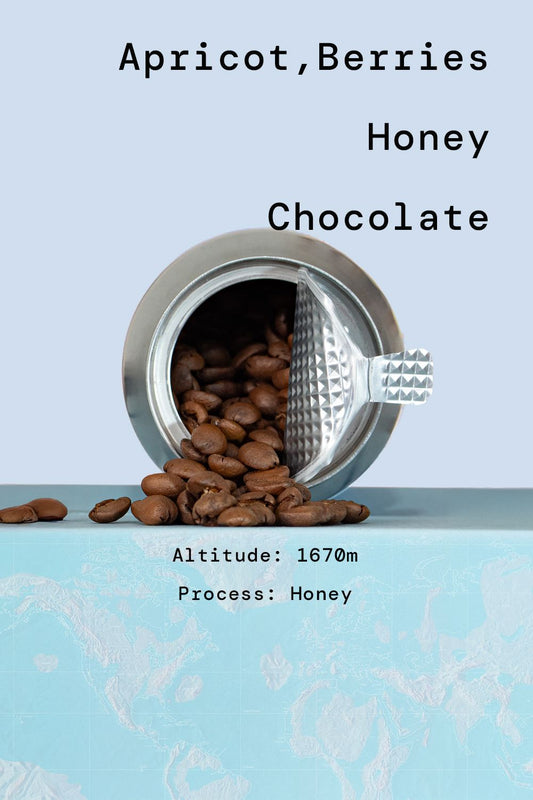

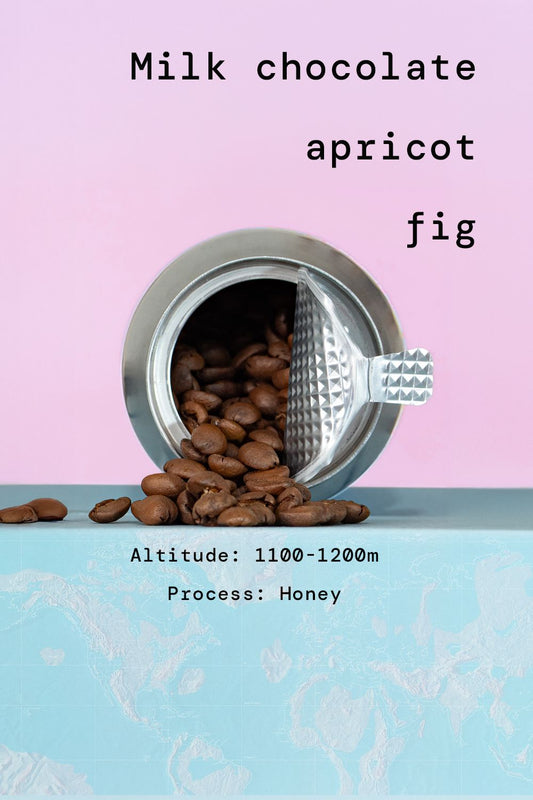

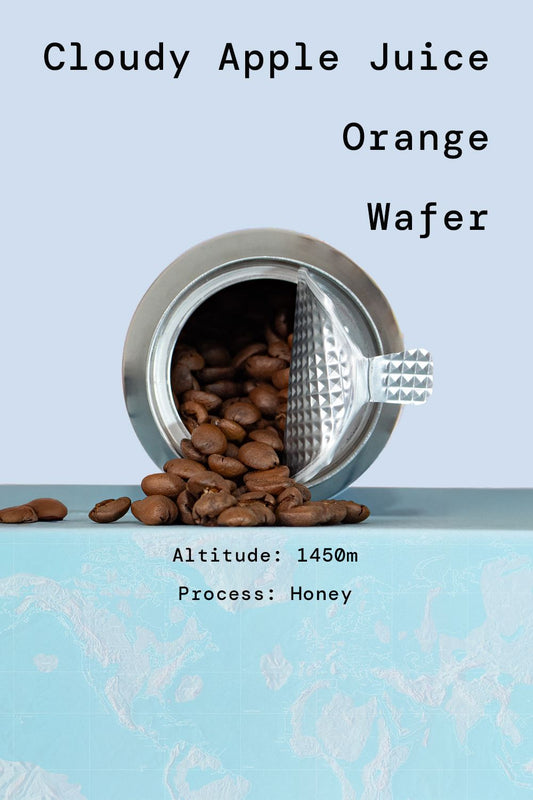

Honey Process Coffees

The honey process, also called the pulped natural process, is a method of processing coffee cherries where the outer skin is removed, but some or all of the mucilage - the sugary layer beneath the skin - is left on the beans during the drying and fermentation process. It is somewhere between the natural process and the washed process, as the seed does not stay in the cherry like with natural coffee, but also doesn’t have the mucilage completely removed like with washed coffee.

It is the glistening, sticky appearance of the pulped seeds which gives this process its name, and depending on how much of the mucilage is removed, honey processed coffees are categorised as either white, yellow, red or black. White honey has the least mucilage and is the closest to being washed, but black honey has the most and is closer to being natural. Changing the chemical composition of the fermentation process also causes changes in the flavour profile, therefore these coffees are generally sweeter and fuller bodied.

During the drying process, the beans are spread out over beds or patios and are regularly turned to ensure even drying and reduce the risk of spoilage, which can take several weeks - once the beans reach the right moisture content, they are hulled to remove any remaining parchment. If any part of this process is not done meticulously it can be easily ruined, the amount of mucilage left on the beans must be precise and the drying procedure carefully monitored and carried out.

This process can now be found in many different countries, but when an earthquake caused water shortages in Costa Rica, it prevented farmers from utilising the washed method and they began using the honey process to conserve water. The coffee farmers and producers of Costa Rica are now world famous for their coffees, having put this method on the map and spent years perfecting it.

The honey process can offer a perfect balance between the fruitiness of a natural coffee and the clean acidity of a washed coffee, and the reduced use of water also adds an environmental benefit.

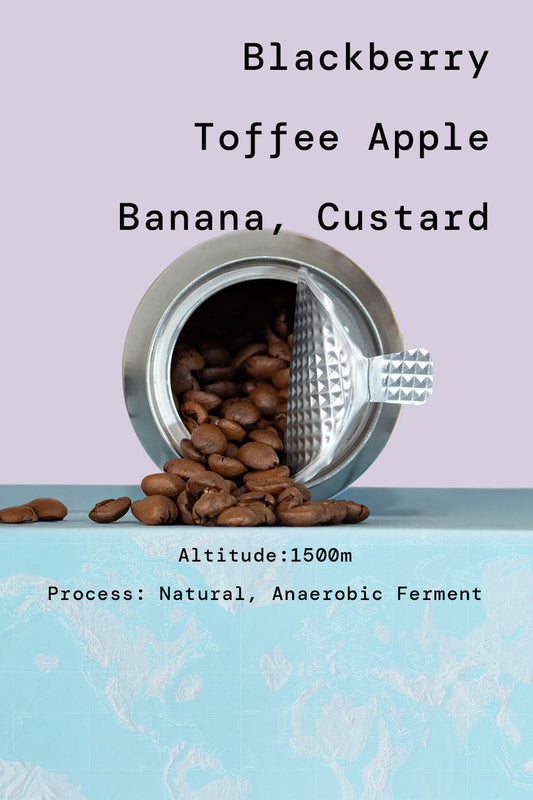

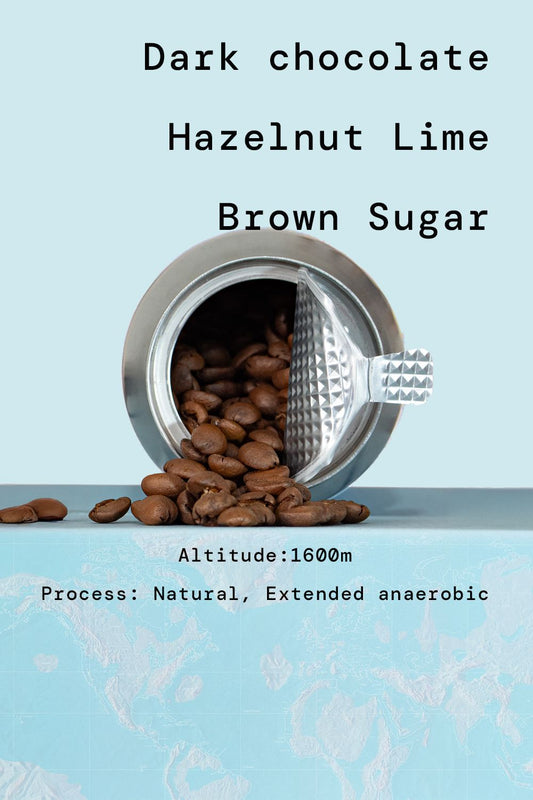

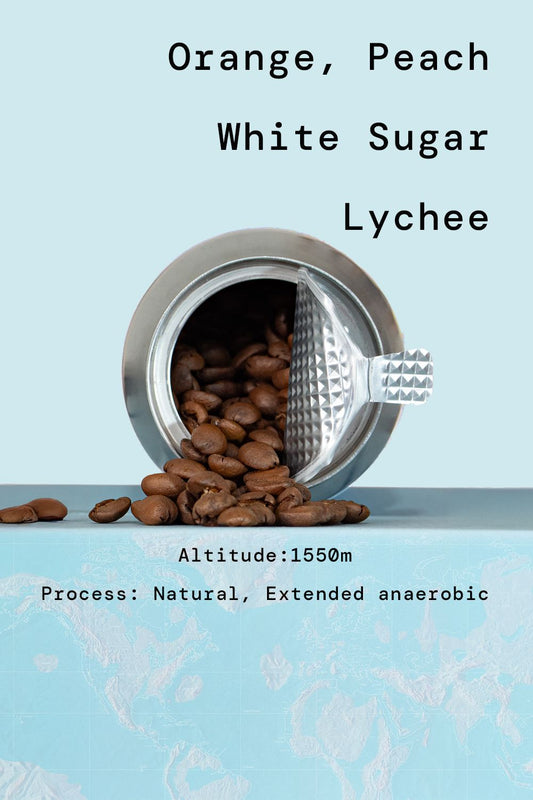

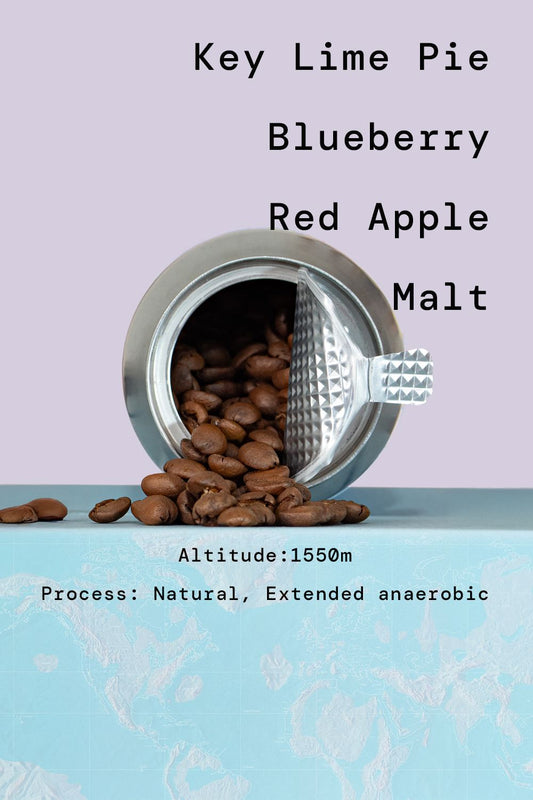

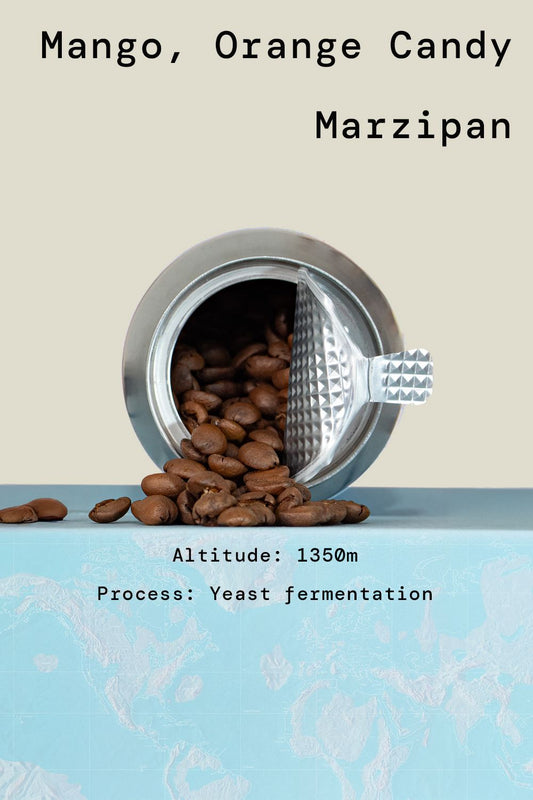

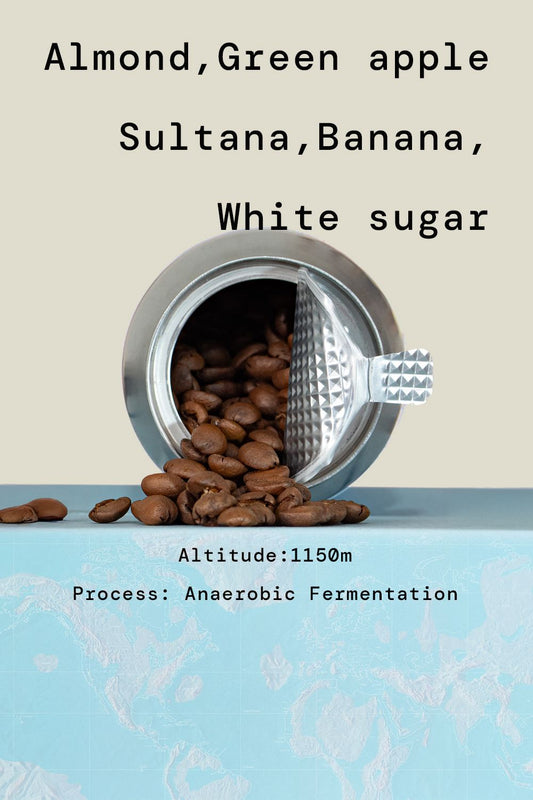

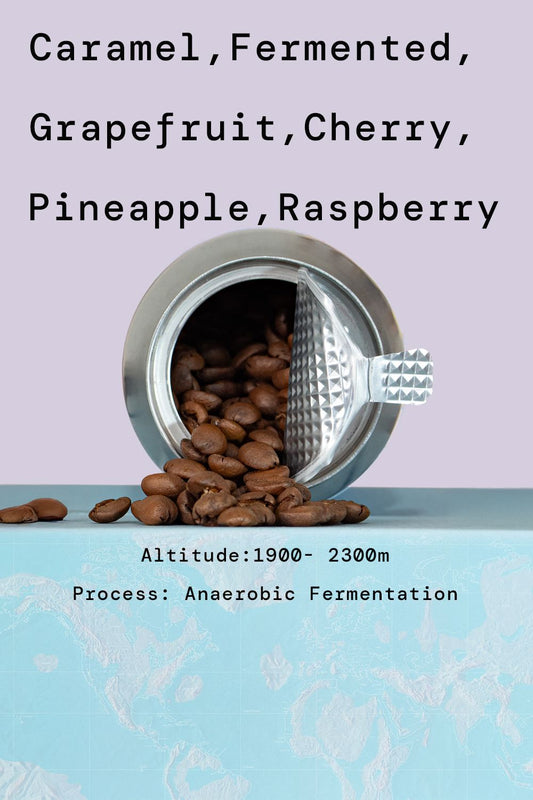

Anaerobic Process Coffee

This style of fermentation can apply to natural, washed or honey coffee, and involves coffee being fermented in pressurised, sealed tanks deprived of oxygen - it is this lack of oxygen which produces particular acids that create distinct flavour profiles. Once the coffee, in cherry form or pulped, is placed into the tanks, a one way valve at the top of the barrels allow the fermentation gases released to push the oxygen out the valve, creating an anaerobic environment over time.

This process can yield a wide range of flavour profiles, depending on the type of anaerobic press used, but generally results in coffees with a fuller body, and a winey flavour, with hints of tropical fruit, fermented cacao and floral notes; a bright and lively acidity is also a common characteristic.

Compared to other types of fermentation, producers can gain a higher level of control and consistency over each batch, and once the right profile for the coffee has been achieved, external factors such as air quality and temperature do not affect the ability to repeat the exact same process for the following batches. This process can also be more environmentally friendly, as it requires less water than traditional wet processing methods. However, one small mistake at any point during the process can be catastrophic, ruining the whole batch, and anaerobic fermentation is expensive, requiring specific equipment and more labour for regular monitoring, therefore many producers cannot afford to use this process.

This innovative technique has gained popularity among speciality coffee producers due to its ability to create distinct and vibrant flavour profiles, allowing for the creation of unique and experimental characteristics which stand out in the competitive coffee market that exists today.